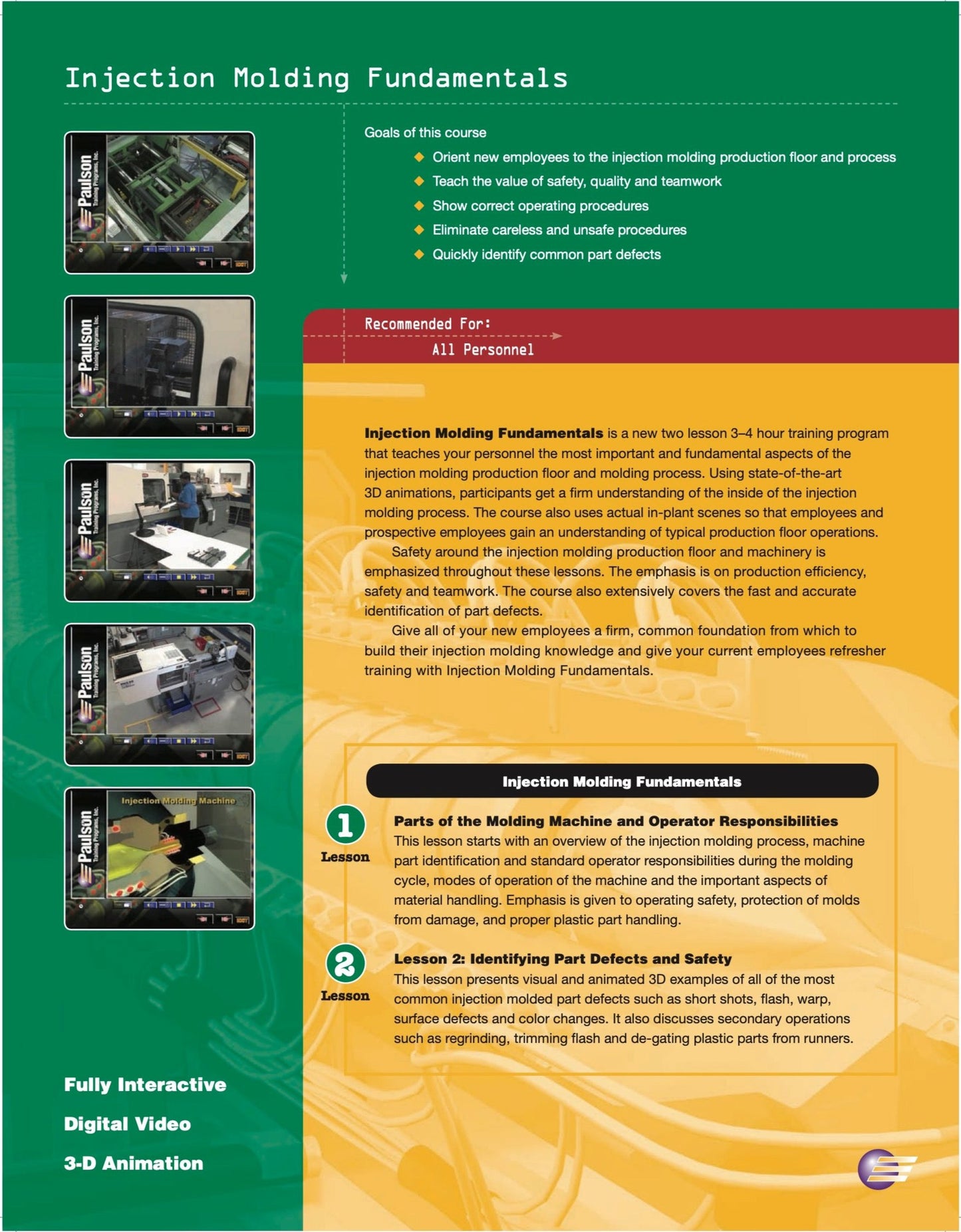

Injection Moulding Fundamentals

Injection Moulding Fundamentals

Goals of this Course:

-

Orient new employees to the injection molding production floor and process

-

Teach the value of safety, quality and teamwork

-

Show correct operating procedures

-

Eliminate careless and unsafe procedures

-

Quickly identify common part defects

Subscribe & Unlock Full Access

Gain immediate access to our library of expert-led training courses, labs, and support.

-

Description:

Goals of this Course:

-

Orient new employees to the injection molding production floor and process

-

Teach the value of safety, quality and teamwork

-

Show correct operating procedures

-

Eliminate careless and unsafe procedures

-

Quickly identify common part defects

-

-

Included Courses:

Lesson 1 – Parts of the Molding Machine and Operator ResponsibilitiesThis lesson starts with an overview of the injection molding process, machine part identification and standard operator responsibilities during the molding cycle, modes of operation of the machine and the important aspects of material handling, Emphasis is given to operating safety, protection of molds from damage, and proper plastic part handling.

Lesson 2 – Identifying Part Defects and SafetyThis lesson presents visual and animated 3D examples of all of the most common injection molded part defects such as short shots, flash, warp, surface defects and color changes. It also discusses secondary operations such as regrinding, trimming flash and de-gating plastic parts from runners. Employees are taught to identify common part defects such as short shots, flash, warp, surface defects and color changes.