Injection Moulding Problems and Solutions

Injection Moulding Problems and Solutions

Goals of this Course:

-

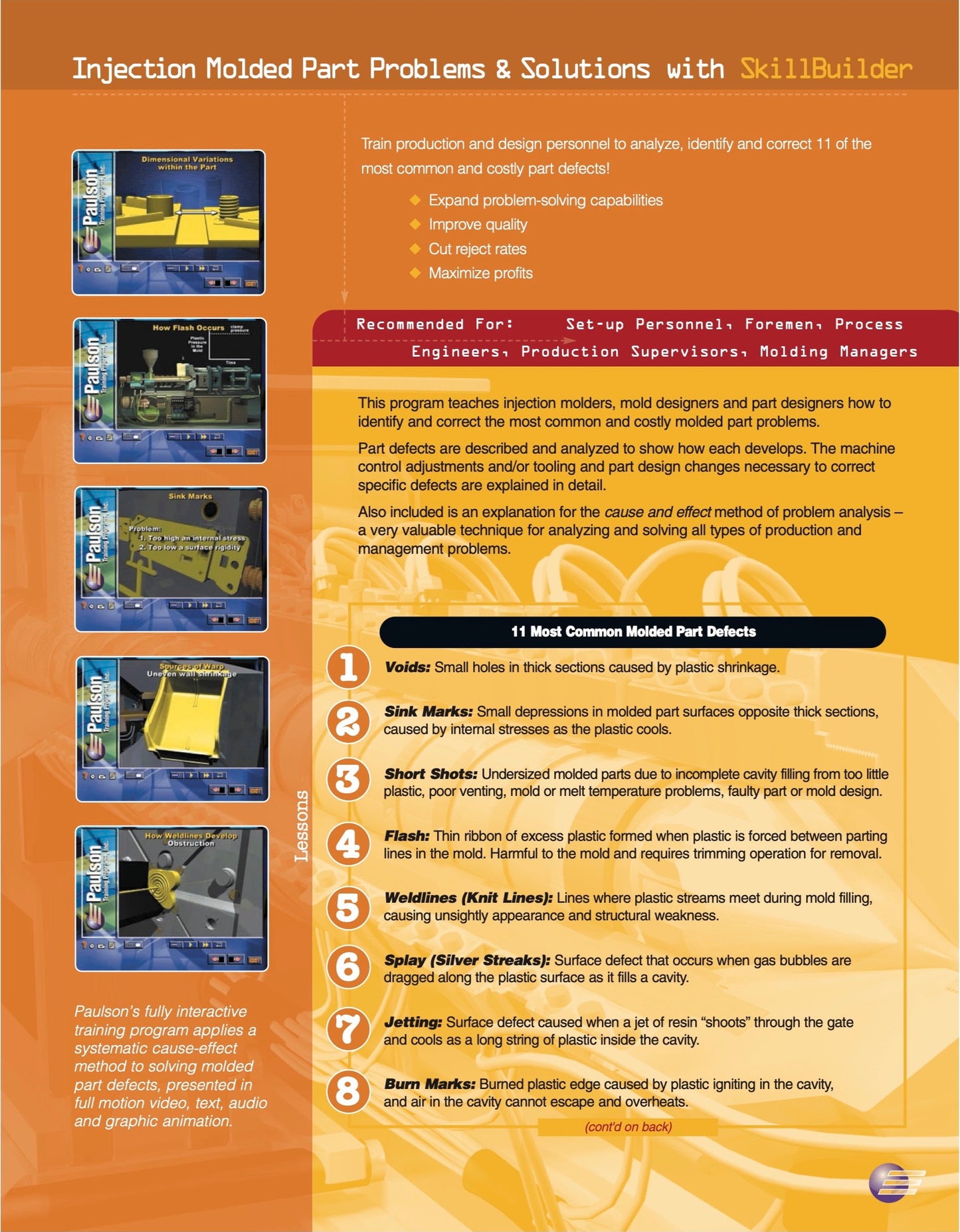

Train production and design personnel to analyze, identify and correct 11 of the most common and costly plastic molded part defects

-

Expand problem-solving capabilities and improve quality

-

Dramatically reduce reject rates

-

Maximize profits through efficient, defect-free scientific molding techniques

Subscribe & Unlock Full Access

Gain immediate access to our library of expert-led training courses, labs, and support.

-

Description:

Goals of this Course:

-

Train production and design personnel to analyze, identify and correct 11 of the most common and costly plastic molded part defects

-

Expand problem-solving capabilities and improve quality

-

Dramatically reduce reject rates

-

Maximize profits through efficient, defect-free scientific molding techniques

-

-

Included Courses:

Lesson 1 – Voids

Lesson 2 – Sink Marks

Lesson 3 – Short Shots

Lesson 4 – Flash

Lesson 5 – Weld lines (Knit Lines)

Lesson 6 – Splay (Silver Streaks)

Lesson 7 – Jetting

Lesson 8 – Burn Marks

Lesson 9 – Warp

Lesson 10 – Cracks and Part Breakage

Lesson 11 – Controlling Molded Part Dimensions